Traditional Utensils - Varanasi

To prepare a brass Kamandalu, initially the scrap brass pieces are allocated and heated in a furnace. The heated brass, which is of liquid form is poured into the pitcher mold and allowed it to form a solid shape. And then the mold is detached from the brass pitcher. Sometimes when the Kamandalu is made in the combination of brass and copper, the top mouth portion and the below portion in the shape of a cup is made of brass using the two different molds. Then the thick copper sheet is cut and welded according to the required measurement and joined in-between the upper and lower parts of the brass Kamandalu. Initially the upper mouth portion of Kamandalu made of brass is fixed to the copper ring by hammering it and shaping it. The gap between the brass and copper is filled by painting the liquid mixer of brass powder and brazing flux powder as a binding agent and heated in the furnace. Once the Kamandalu’s middle portion of copper and the top brass portion of Kamandalu is attached firmly by fixing and heating, it is allowed to cool for some time. Then the down brass part of Kamandalu is attached in the same way to the other side of the copper and heated in furnace and cooled. When it is only the brass Kamandalu then once the pitcher mold is taken, it is allowed for cooling and then it is neatly polished by the polishing machine. After the pitcher is ready a hole is made according to the requirement, in the area where the snout has to be attached. A brass snout is also made by using a mold and is polished. And then it is attached to the pitcher and the mixer of brass powder and brazing flux powder is applied and heated and then buffed completely. A thick sheet of brass is cut accordingly and attached in a semicircular manner at the mouth of the Kamandalu’s either sides as a handle. Thus the traditional brass Kamandalu is prepared and sold at Varanasi.

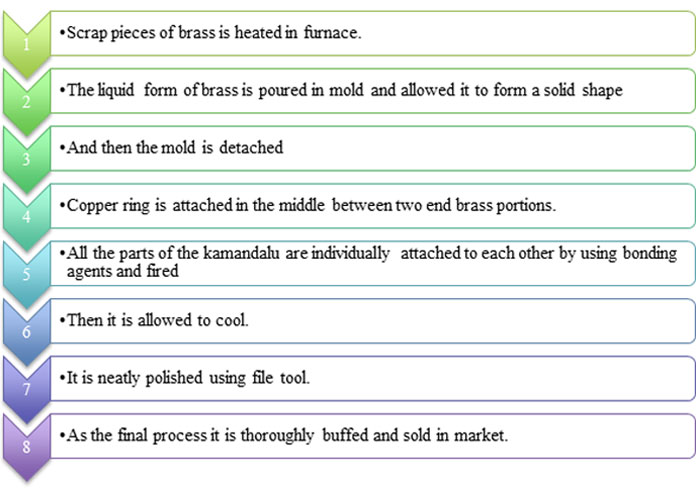

Flow Chart: